Download Catalogue

HDPE/PPR Pipe Extrusion Line - (FLOWEX)

Reliable and extremely versatile Rajoo Bausano single-screw extruders from E-GO series are designed for transformation of thermoplastic polymers such as polyolefins (HDPE, PP).

- Output range :- 150 to 2000 kg/hr

- Pipe dia :- 15 to 800

- L/D ratio :- 40:1

HDPE/PPR PIPE EXTRUSION LINE SALIENT FEATURES

Single Screw Extruder

- High output 40 L/D extruder series designed for the manufacturing of Polyolefin

- The product range comprises extruders with screw diameters from 30 to 120 mm

- E-GO series extruders with a barrier screw and spiral grooved feed section enables melt homogenization at much higher output levels at lower energy consumption

- Possibility to add additional layers

- The hemispherical cavities of the screw mixer force the raw material travelling along the barrel continuously changing direction, causing shearing and cutting action to the melt

- Direct coupled gearbox design ensures minimum transmission loss

- Melt temperature and pressure sensor for ease of processing

- Versatile extruder designed for HDPE, PP, PS, ABS, PMMA, PC

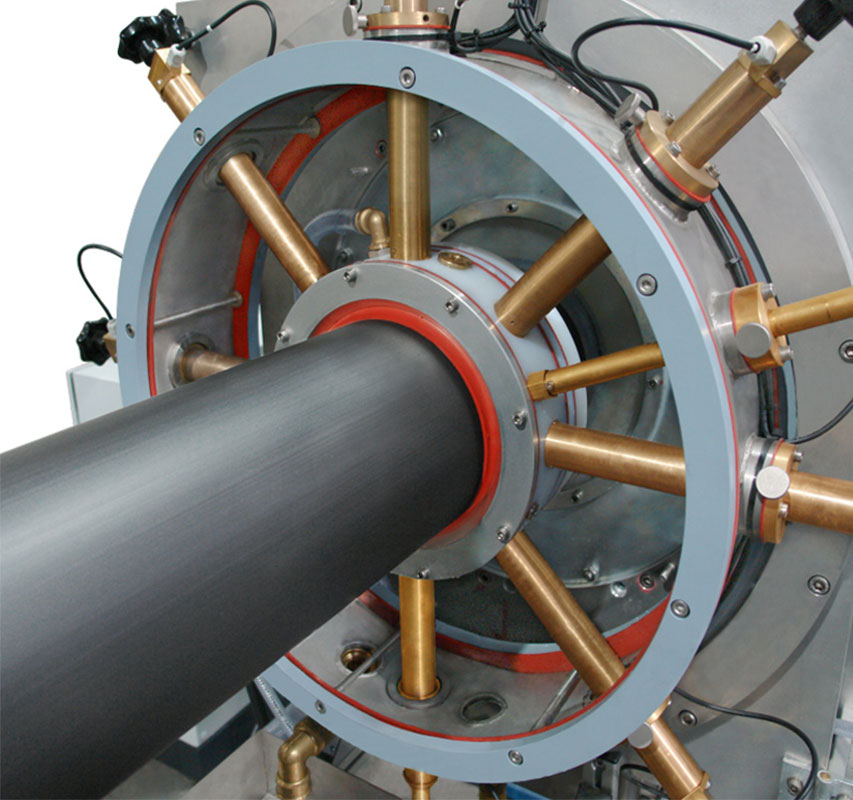

Cylindrical spiral die head (CSD)

CSD die with cylindrical spiral mandrel is state-of-the-art and provides:

- Optimized layout for rheological and thermodynamic criteria

- Number of overlaps almost unlimited, thus excellent thickness distribution and broad range of operating parameters

- Merging of melt streams according to specific flow behaviour of polymers

- Compact design and low axial forces

- Ease of handling

Side fed cylindrical spiral die for horizontal extrusion with spiral mandrel distribution for production of HDPE pipe. The die head allows die lips gap to be sized to provide the optimum velocity and pressure balance characteristics necessary for uniform thickness of pipe.

Efficient self-cleaning is attained through optimum design of the flow channels. The entire flow path is highly streamlined and highly polished to eliminate all dead spots. The surfaces which are in contact with melt are especially hard chrome plated and polished. This ensures rapid flushing and thereby shorter non-productive times during colour change.

The die head is mounted on sturdy support and incorporates adjustable screw and locking device.

- Advanced calibration sleeves enable faster cooling to achieve higher line speed with excellent pipes surface.

- Tanks are made of stainless steel for high corrosion resistance and longer useful life. Unique design for superior cooling efficiency. Multi axis adjustment system allows quick and precise positioning.

- Servo controlled direct drive haul-off unit Multi track haul-off, Independent AC Servo motor and drive for optimum pulling force and to prevent ovality even for large diameter and thin wall pipes

- Planetary Cutter ensure smooth cut and dust free production. Swarfless cutting for PE pipes

- Gravimetric system to control weight/meter

- Co-extrusion for multilayer pipes

- Jockey extruders for colour stripe

- Hopper loaders and dryers

- Ultrasonic wall thickness measurement

HDPE/PPR PIPE EXTRUSION LINE APPLICATIONS

- HDPE / PP Irrigation pipe

- Plumbing pipes

- Column pipes

- Sewage pipes

- Industrial pipe (Telecom, Chemical etc)

- Gas distribution pipe

- And many more