About Us

Every great manufacturing accomplishment is a fine blend of two ingredients - "Technology and Infrastructure". Rajoo Bausano Extrusion Pvt. Ltd. is a classic example of one such initiative. Rajoo Engineers Ltd. has entered into a Joint Venture with Bausano & Figli SpA, Italy to manufacture and market pipe and profile extrusion lines including for wood plastic composite in India, with a special emphasis on African, Gulf and SAARC markets.

Rajoo Engineers Ltd. is a leading and one of the fastest growing manufacturers of Plastic Extrusion Machines in India. Having commenced its operations in 1986, Rajoo is today considered as an undisputed global player for complete solutions provider for film extrusion, solid and foam sheet extrusion, thermoforming, non-woven plant and round & flat drip irrigation pipe plant. The biggest testimony of customer satisfaction for Rajoo is that during the past decade, 50% of the sales are generated by repeat orders from existing customers. Rajoo is equipped with prestigious certification like ISO: 9001: 2000 and it is the first plastic processing machinery manufacturer in India selling 'CE' conforming machines complying fully with EEC safety regulations, a mandatory requirement for plants operating in Europe.

Bausano & Figli SpA, Italy was established in 1946. The company has 68 years of rich experience in plastic processing machinery. Bausano & Figli was the first company in the world to develop the parallel-counter rotating twin screw extruder. It's state of the art manufacturing facilities are located at Rivarolo Canavese & Marnate in Italy and Sao Paulo in Brazil. In 1982, Bausano innovated and patented the revolutionary transmission system, known as MULTIDRIVE, with enormous advantages in terms of the durability, performance of the extruder and energy savings.

Rajoo Bausano Extrusion Pvt. Ltd., the new JV Company is a combination of Rajoo's world class infrastructure and Bausano's sublime pioneering technology. Through this unique JV, customers will have world class technological products at affordable price levels.

basic instinct

A remote and rural location, abounding in human values, flourishing in nature but lacking in almost all amenities of modern living has inculcated a distinct sense of professionalism in us.

PROFESSIONALISM OF A SPIRITUAL KIND

- Where economies of time are not sacrificed to achieve the economies of scale.

- Where continued improvements and not static solutions are at the helm.

- Where dialogue and not propaganda is the means of communication.

- Where human skills and not the machines alone matter.

- Where most complex technological advancements and - not only price competitiveness - are taken as a challenge.

PROFESSIONALISM THAT MAKES THE DIFFERENCE

Relatively young, targetting plasticizing capacity rather than number of installations. With enduring zeal and dexterity of our people, building plants with sculptor's precision, working relentlessly, always there with a helping hand and caring heart whenever customers need us. Professionalism not camouflaged with bureaucracy.

Infrastructure

The state-of-the-art design and manufacturing facilities in sprawling green acres and built-up area of 20,000 sq. mts. are located on the outskirts of Rajkot, Gujarat, one of the most industrious and vibrant states of India, famous for its engineering skills. World-class integrated facilities comprise design and development, tool-room, die shop, metal treatment shop, fabrication shop, paint shop, assembly shop and testing shop.

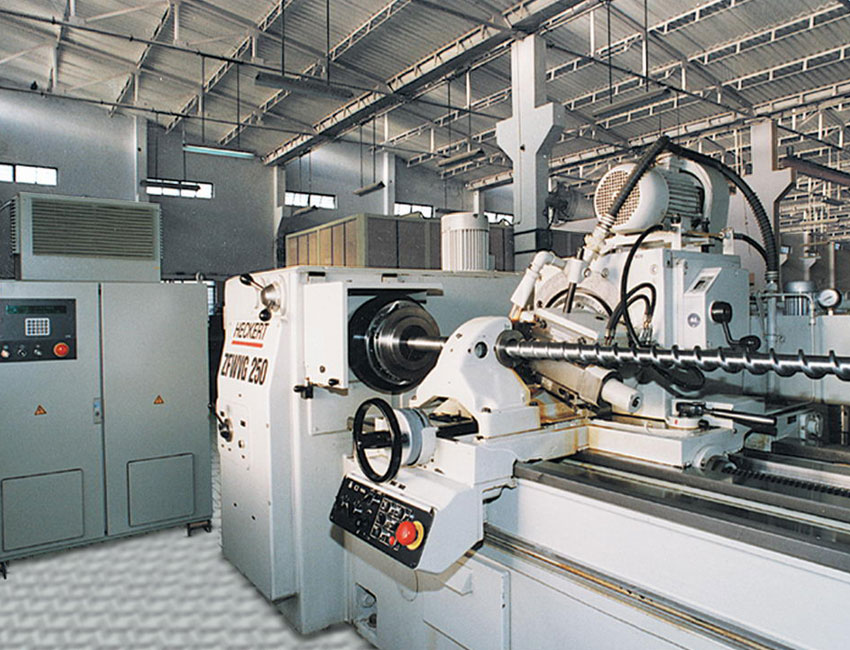

Shree Yantralaya - a tool room

The state-of-the-art tooling zone, Shree Yantralaya goes a long way in ensuring consistently higher accuracy levels in all critical components.

'Shree Yantralaya' presents an immaculate approach helping the company refine the scope of 'Excellence in Extrusion'. Access to these latest machining technologies and techniques empower the company to enhance customer delight. Ninety percent of the hot parts and air ring components of the machines built by Rajoo are now CNC machined resulting in higher repeat accuracy, quick turn around time and easy replaceability of components.

Enhanced quality components produced in a controlled air conditioned and dust free environment, with better workmanship, accuracy and quick turnaround are attributes that necessitated this significant investment in 'Shree Yantralaya' which is now the abode for machine tools such as:

- 4 axis CNC turning centre - Feeler, Taiwan

- CNC turning centre - Jyoti, India

- 4 axis double column VMC machine - Huron, France

- 3 axis high speed milling centre - Huron, France

- 3 axis VMC machine - Jyoti, India

- CNC vertical turning lathe - You Ji, Taiwan

- CNC thread milling machine - Heckert

- 2 axis water jet cutting machine - KMT, Jetline, Germany

- Universal cylindrical grinding machine - Smithson, India

- 3 axis CNC smart turn lathe - Pinachio, Spain

These machine tools employs precise machining technology to produce extremely high-quality components. Digitally designed complex component are seamlessly transposed to these machine tools directly, eliminating the need for human intervention and related errors.

To ensure that the products consistently live up to and in fact, surpass, the performance standards, Rajoo uses the most advanced machine tools and operational techniques available worldwide. Engineering and manufacturing departments are integrated through a digital net-work to ensure consistency, reliability and collaboration.

Ensuring Quality Through Various Processes

The strong integration with polymer suppliers and processors allows the choice of most suitable line for the customer's requirement. Various components and assemblies are designed using various computer simulations ensuring quality of the component with stage wise inspection of the components and assemblies using precision inspection tools, jigs and fixtures.

Huge and Well-Equipped Assembly Shop

The huge and well equipped assembly shop is partitioned to accommodate machines of different heights and lengths. Highly professional and skilled craftsman assemble the lines. The machines are tested thoroughly and performance is checked according to customer's specifications before dispatch. The testing bay is capable of accommodating several pipe plant lines at a time.